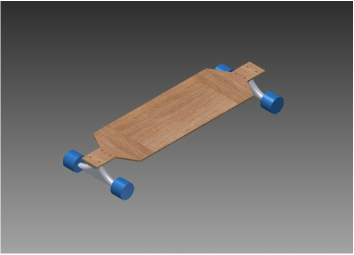

Folding LongboardPursued a personal, self driven design process to develop a commercially viable foldable longboard skateboard over the course of the 2014 summer. This project is still on-going, and a 4th prototype is currently being produced.

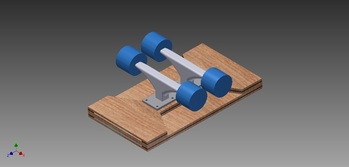

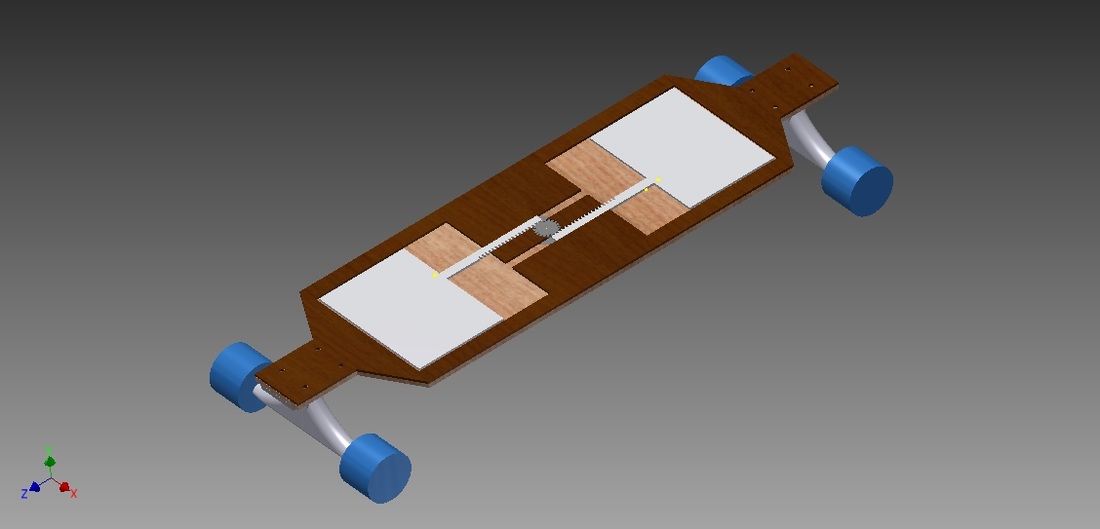

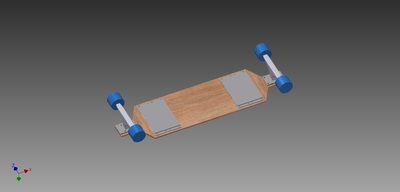

The original design was based off of using two sliding metal plates that could be extended or retracted from the middle section of the board. When riding, the three sections of the board would be all laid out flat, and the plates would be extended (by the use of a rack and pinion inside the board) to span the joint between the segments of the board. These plates would support the rider's weight and keep the board from folding while riding. To fold the board, the plates would be retracted into the middle section of the board.

|

|

Consulted with professors to gain the information needed to test the practicality of the design

|

Modeled and analyzed the structural integrity of the design using 3d computer aided design software, Autodesk Inventor

|

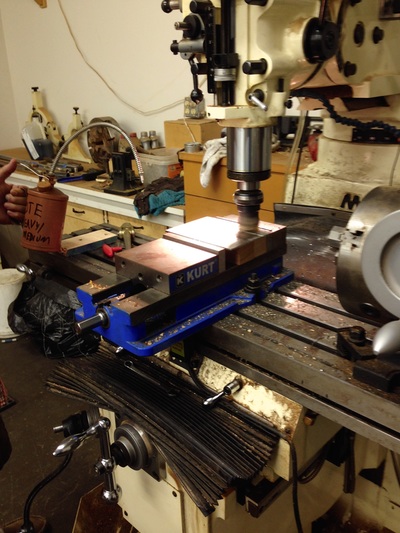

Selected the materials for the board, and experimented with materials during the process of manufacturing several prototypes of the design

|

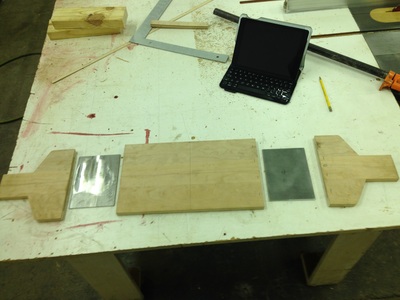

Version 1

The first prototype of the board followed the original designs to encase sliding metal plates inside the wooden structure of the board. One layer of wood one top, a middle layer of wood that held the plates, and a bottom layer of wood. This prototype (along with versions 2 and 3) were mainly to test the structural integrity of the design. This board failed shortly after I began riding on it because the top and bottom wooden layers were not strong enough to handle the stresses that the metal plates exerted on them during riding.

Version 2

To strengthen the wooden structure of the board from the previous design, I added layers of fiberglass to the main layers of the board. This design used the same basic board design as the previous prototype, except with fiberglass re-enforced wood. The fiberglass re-enforced board failed because the bond between the fiberglass and the wood was not sufficiently strong enough to support the stressed caused by the weight of a rider. When I first rode this prototype, the board tore apart into two sheets (top and bottom) along the seam where the fiberglass was bonded to the wood.

Version 3

For the third version of the board prototype, the basic design was changed. Instead of having the metal plates that are used to support the joints between board sections be sandwiched between two layers of wood, the board was built such that the top layer of the board is a very strong layer of wood and the plates were attached to the board by aluminum brackets mounted to the bottom of the board. This way, each side of the metal plates (the board on top and the brackets underneath) would be individually strong enough to withstand the forces created when a rider stands on the board. This design (as well as the previous two designs) of the board used aluminum plates to span the joint between the longboard parts, and the aluminum plates were the feature that failed during testing of this board design. The aluminum was not strong enough to support the weight of the rider, and underwent plastic (permanent) deformation when a rider stood on the board.

Version 4 - In progress

After reflecting on the previous prototypes of this board, it became clear to me that, while I felt confident that I could make the board structurally strong using the most recent design, there were several usability factors (mostly the friction between the metal plates and the board when the plates would try to be retracted) that made this design impractical to continue to pursue. Therefore, I am currently working on designing a 4th prototype that uses a very different design than the previous 3 prototypes.